BUILT AROUND YOU

GKS packaging understands that no two packaging requirements are the same. That's why we have designed modularity and flexibility into our machines. This allows us to build a solution that not only perfectly suits your current demands, but can also develop and expand with your changing needs.

GKS is a family firm specialized in high-uptime, no-nonsense, cost-effective, flexible packaging solutions for all businesses. GKS was founded in the family garage by father and son Eli and Ivo Geukes in 2000. The sale of three machines in their first year helps the duo finance a drilling and milling machine, lathe and welding machine. In the second year, the company moves to the Ekkersrijt industrial estate.

In 2017 the company moves to a new facility at Steenoven 18 in Eindhoven, where the adjacent plot offers scope for expansion. Over the past 20 years, GKS Packaging has grown from two to 26 employees and developed one new machine every year on average.

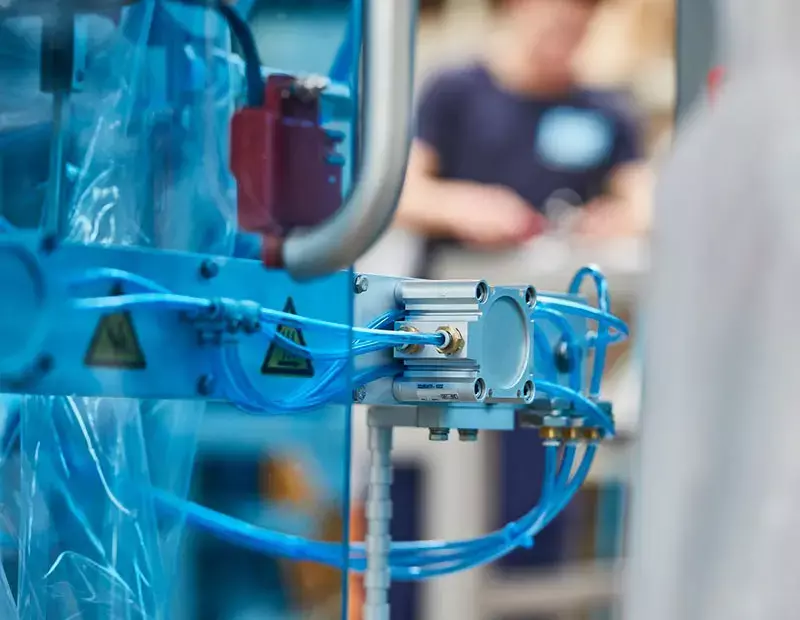

We currently offer a broad, integrated range of standalone machines as well as complete weighing and packaging lines. Our vertical form, fill and seal machines are entirely developed, designed and built in house. We also offer weighing systems, dosing systems, conveyor belts and platforms built to customer specification. Today, more than a thousand of our solutions are installed on all continents.

Our aim is to challenge the status quo and make your life easier with smarter machines and processes. Find out what we can do for you today!

Benelux

Global

Father and son start GKS Packaging at home in the garage and do market research.

Introduction of the GKS-Easypack.

Move to first official company premises at Ekkersrijt 1331 in Son.

Development of UP machine series, a further development of the successful Easypack.

Market demands a new compact type of packaging machine; GKS develops the CP 300.

Move to second production facility, purchased on Ekkersrijt industrial estate.

Export to more than 10 countries.

Development of revolutionary vertical packaging machine FLOW: servo driven, hygienic design and fully wet cleanable on the inside and outside.

Machine number 500 is installed on customer premises.

Further development of dealer network and increase of export sales. GKS machines installed on all continents.

Development of 'GKS new machine platform', a completely open construction with modular design.

Eli Geukes passes away on the 21st of December 2015. A huge loss, but Eli's spirit is deeply rooted in GKS Packaging's DNA and continues to motivate us.

Move to a new premises in Eindhoven, with production facilities more than 2.5x larger than former factory: ready for the future!

Introduction of the EP 250, successor to the EP 200 which started everything.

Machine number 1,000 is installed on customer premises.

Introduction of LEAF. This machine is specifically developed to produce paper bags out of 100% recyclable and compostable paper mono material.

Introduction of MINI, an extremely compact, competitive and frameless VFFS machine.

Start of the construction activities to expand the current premises.

Introduction of FLEX-DC. This machine is developed to produce DOY-bags and Corner seal bags.

Redesign of revolutionary vertical packaging machine FLOW: continuous running, servo driven, hygienic design and fully wet cleanable on the inside and outside.

We're always happy to advise you or help you find the most efficient and affordable solution to your packaging challenges. Get in touch today - without obligations - to ask any questions you may have!