GKS packaging solves your real-world challenges in the easiest way: by delivering ultra-reliable, cost-effective, modular packaging machines, made to meet your requirements. After all, why make things more complicated than they need to be?

We offer a complete range of effective, hygienic and integrated solutions for different types of food and non-food packaging. Need to bag and seal fresh product? Package medication or medical supplies? Sort and pack nuts and bolts? We can provide the ideal solution that maximizes output, minimizes throughput time, and handles products to be packaged with the utmost care!

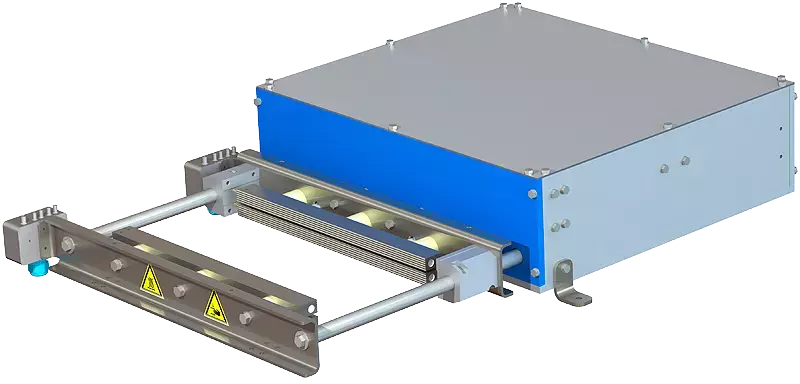

We're proud of our extensive, fully integrated vertical form, fill and seal machines (vffs) for applications such as food packaging. Everything is designed and built in-house: often copied, never emulated.

GO WITH THE FLOW:

New modular thinking has resulted in the FLOW series, with its unique hygienic design, completely stainless steel construction, high packing speeds and user-friendly control.

We have an excellent track record in flexible, high-uptime solutions for a wide range of customers, from small companies to large industrial packaging houses. Tell us what you need and we’ll provide you with the most cost-effective, innovative solution in vertical form, fill and sealing (vffs). Fast. And hassle-free. Just ask any of our long-standing satisfied customers.

Our offering covers packaging machines, multihead and linear weighers, auger fillers, volumetric cup fillers, pumps, conveyors (infeed and take away), additional items (platforms, packstations and turntables) and refurbished machines. | TAKE ME TO THE OVERVIEW >

Simplicity is the ultimate sophistication

At GKS packaging, we are dedicated to providing you with the highest levels of efficiency, reliability, ease of use and value for money. We do this by completely rethinking traditional approaches to engineering, based on real-world requirements. Our machines do exactly what they need, guaranteeing the highest possible productivity with the lowest possible downtime. | CHECK OUT MORE >

Here at GKS, we understand what issues packaging plants face every day. Space is at a premium, and expansion is always a possibility, so machines need to have a limited footprint – without compromising on quality and serviceability.

Professional skill, service-orientation and a flexible attitude are requisites for a job at GKS Packaging. | MORE INFORMATION >

We're a family company with a hands-on approach and years of packaging industry experience. Our engineers are recruited for their skill, creativity and ability to listen. That's how we know you'll get a solution that does exactly what it needs to. | MORE >

GKS Packaging

machines installed

happy customers

(and counting)

Our designs are all about ease of use, robustness and the highest levels of hygiene. We make sure you’ll be able to keep up with the growing demand for packaging that meets ever-higher standards of safety, cleanliness and quality. Without the extra cost.

Our machines are built from recyclable materials and feature low energy and compressed air consumption. Modular design makes it easy to replace modules, thereby extending machines’ operational lifetime. This approach also means machines can easily be dismantled and recycled.

Life is really simple but we insist on making it complicated

Would you like to find out more about any of our products and services, or discuss any packaging challenges you may have? | GET IN TOUCH >

Would you like to find out what our solutions can do for you? Call us for a demo!

To ensure we can provide the best possible service in the shortest possible time frame, we work very closely together with an extensive dealer network of companies that provide local sales and after-sales service. Find out which of our partners is closest to you! | MORE INFORMATION >

Steenoven 18

5626 DK Eindhoven

The Netherlands