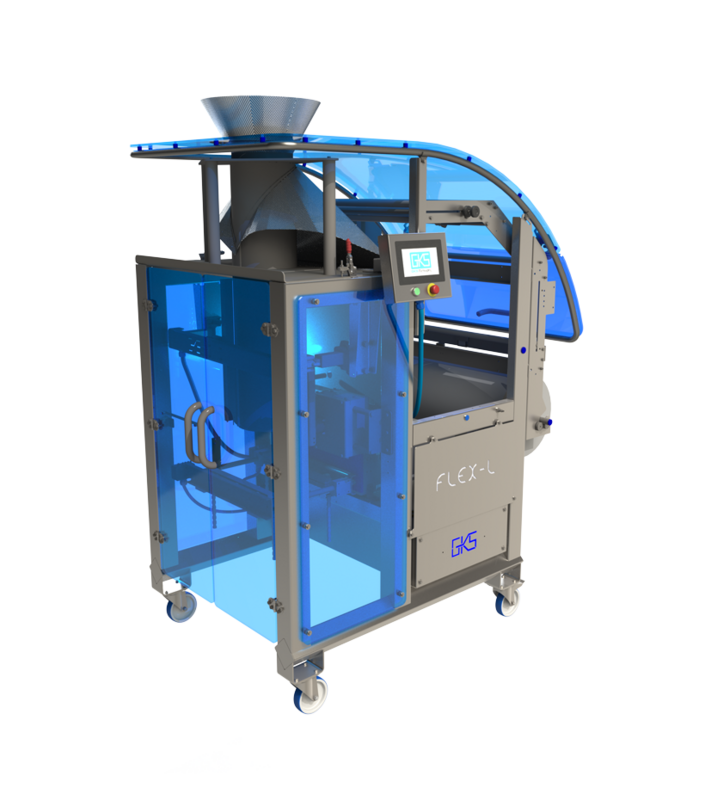

The FLEX-L offers a hygienic design and is constructed from stainless steel. Together with the open construction, this makes the machine very easy to clean. The FLEX-L has been developed for both industrial packaging houses as well as smaller packers who need a flexible machine for their continuous packaging process.

The FLEX-L is available in three versions:

1) FLEX-L: Pneumatical driven sealing system

2) FLEX-L: Servo-driven sealing system

3) FLEX-L: Netpack configuration

These machines can handle a wide variety of packaging formats (75 to 350 mm bag width and unlimited bag length) and the capacity is up to 70 (when servo configured) bags per minute.

The Netpack configured machine makes pillow bags from net material, PE, PP and laminated film and block bottom bags from a flat film on a reel. A continuously heated sealing system with interchangeable seal profiles can handle the wide variety of packaging materials. The integrated handle system can create a handle in the upper part of the bag. The bag length is determined by an encoder, which guarantees a high degree of accuracy. The capacity is up to 40 bags per minute.

| FLEX- L | FLEX-L Servo | FLEX-L Netpack | |

|---|---|---|---|

| Bag width (pillow) | 75 - 350 mm | ||

| Max. bag length | Unlimited mm | ||

| Max. bag length per sealing step | 480 mm | ||

| Max. production speed | 50 bags/min | 70 bags/min | 40 bags/min |

| Film thickness | 25 - 120 µ | ||

| Core diameter | 76 mm (3") | 152 mm (6") | |

| Max. film width | 750 mm | ||

| Max. outer diameter film roll | 320 mm | 600 mm. | |

| Voltage | 230 V, 50/60 Hz | 380 V, 50/60 Hz | |

| Power during production | 1,200 Watt | 1,500 Watt | 1,200 Watt |

| Air consumption | 6 bar, 150 l/min | 6 bar, 100 l/min | 6 bar, 200 l/min |

All dimensions and specifications are indications based on standard set up. Final details depend on customer specifications.

We're always happy to advise you or help you find the most efficient and affordable solution to your packaging challenges. Get in touch today - without obligations - to ask any questions you may have!